Lightning is a discharge of electricity. A single stroke of lightning can heat the air around it to 30,000°C (54,000°F)! This extreme heating causes the air to expand explosively fast. The expansion creates a shock wave that turns into a booming sound wave, known as thunder.

Lightning strikes can damage equipment and instrumentation, disrupt service, and cause injuries. While estimates vary, lightning damage is generally considered responsible for up to 20% of all power outages in the U.S. each year and causes more than $1 billion of property damage annually.

A direct lightning strike delivers damaging energy, which even the most robust electrical devices and systems cannot withstand if protection measures are not correctly taken. Reduce the risk of lightning damage, direct or nearby, with the installation of a lightning protection system.

The lightning rod has been the primary means of protecting assets from lightning damage for over two centuries. However, attracting lightning is not something that owners of multi-billion dollar oil and gas facilities want. Instead, LEC uses charge transfer technology to prevent direct strikes by lightning and protect energy assets whose electronic components can be knocked out by lightning in the blink of an eye.

How does it protect the oil and gas industry from lightning damage?

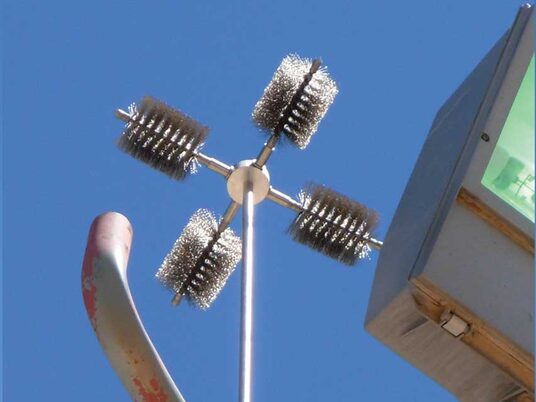

We call our lightning damage prevention system the Dissipation Array System (DAS), which is intended to prevent a lightning strike from occurring within a protected zone or area. The system prevents lightning strikes by collecting the induced charge developed by thunderstorm clouds from a protected area of the earth and transferring this charge through the ionizer into the surrounding air.

The system involves one or more ionizers, a down conductor, and a charge collector. The latter is an interconnected system of grounding electrodes and conductors designed to collect and funnel electrical charge to the ionizers. The down conductor provides the electrical connection between the charge collection and the ionizers, which provides a means for point discharge to take place.

The charges transferred to the air can act in one of two modes – collection, which establishes a preferred conductive path for the lightning leader, and prevention mode, which reduces the electric field intensity to the level that delays the formation of an upward streamer from the protected area.

Do you worry about how lightning damage can affect your facility or property?

Connect with us for a worry-free solution.